A group of researchers from Osaka Metropolitan University has recently found and developed an innovation to detect contamination in food earlier than the standard waiting time. Conducted at the Graduate School of Engineering, this research was led by Hikaru Ikeda. The group consisted of Akira Tokonami, Shigeki Nishii, Xueling Shan, Yojiro Yamamoto, Yasuhiro Sadanaga, Zhidong Chen, and Hiroshi Shiigi. Their publication titled, “Evaluation of Bacterial Activity Based on the Electrochemical Properties of Tetrazolium Salts” was published on August 10, 2023.

This research aimed to address the issue of how conventional measurements are often not sensitive enough to detect rare species and require the enrichment of pathogens first. Also, current safety and quality tests for detecting bacteria, fungi, and virus contamination in food usually take 48 hours or more. The results of food contamination testing are only available after the products have been shipped from the factory, which could lead to potentially fatal consequences.

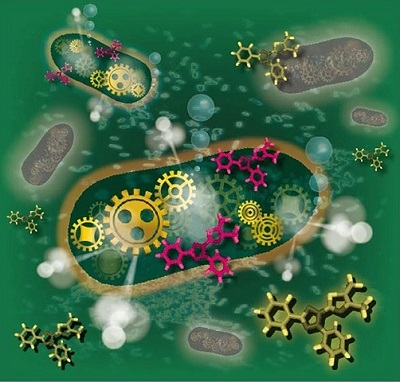

The study focused on utilizing the electrochemical properties of tetrazolium salts (MTT) to develop a simple method for evaluating viable bacterial counts. Measuring viable bacterial counts is crucial to determine whether water is safe to drink or swim in or whether food products are safe for consumption.

The standard determination of bacterial concentration utilizes petri plates. This involves spreading a small amount of the sample bacteria on these plates and letting them grow for about 24 hours, then counting them to know the number of living bacteria in the original concentration. However, waiting 24 hours for the result is not ideal.

Utilizing MTT as a method to detect food contamination found by the research group was easy to do and did not require complicated equipment. MTT creates formazan as a reaction when it encounters live tissue, in this case, live bacteria. When MTT comes into contact with live bacteria, it will turn a specific color, indicating their presence. The research findings successfully reduced the inspection time of food contamination testing from 2 days to 1 hour regardless of the bacteria species.

New technology that significantly reduces the time it takes to measure viable bacteria in food

This technology accurately measures viable bacteria in food within 1 hour, as opposed to 2 days, regardless of bacterial species. Unlike existing technologies, this method does not require complicated operations or expensive equipment

Credit: Hiroshi Shiigi, Osaka Metropolitan University

Despite the advantages of this research, there are still some challenges in developing this food testing method. This method might not be specific enough to identify feasible bacteria because other bacteria could interfere and provide false-positive results. Additionally, the method may be quite insensitive in detecting low levels of bacterial contamination. Moreover, tetrazolium salts exhibit cytotoxic effects to some bacteria, affecting their viability and growth during the experiment.

This method is still in the research stage. There has not been an official statement from the researchers regarding when this food testing method will be adopted or implemented in the food industry.

Several factors need to be considered before the method’s public release and usage. This involves the approval for regulation, demands from the market, developments of the technologies, and the cost-effectiveness of the method. Professor Hiroshi Shiigi added that the researchers will continue to optimize the measurement conditions and expect to see the development of a portable sensor in line with the development of research aimed at practical applications.

About the Author

Alia Pramesti Olifia Rahman

Olifia Rahman, or Olif, is a writer volunteer in AYO POST. As a student at a senior high school, she broadens her experience by joining a few external organizations remotely mostly as a writer. She prefers to convey her thoughts and feelings through written pieces rather than verbally. Aside from writing, she likes to read, listen to music, and take a rest.